The Importance of Ductwork Fabrication in the Philippines

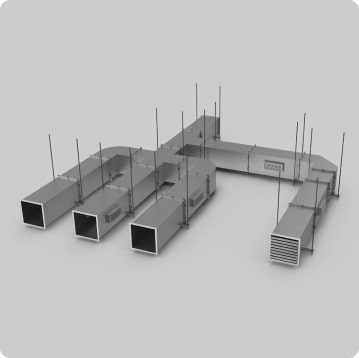

Proper ductwork fabrication is crucial for the optimal functioning of HVAC systems that provide conditioned air throughout a building. It involves the creation of ducts that meet precise specifications such as size, shape, material selection, airflow, and pressure requirements.

For businesses in the Philippines, partnering with a reputable ductwork manufacturer is essential. Here are some key reasons why ductwork fabrication plays a vital role in the HVAC industry in the Philippines.

Well-Designed Ducts

A ductwork manufacturer in the Philippines plays a critical role in ensuring that ducts are well-designed to meet the specific needs of a building, taking into account various factors such as layout, size, and airflow requirements.

The fabrication of properly designed ducts enables the even and efficient distribution of conditioned air, improving indoor air quality, and reducing energy consumption, resulting in significant cost savings.

Assures Durability and Longevity

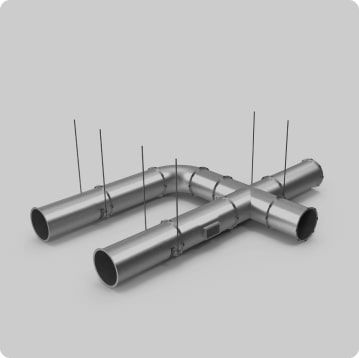

By ensuring the ducts are well-constructed, ductwork manufacturers in the Philippines are less susceptible to leaks, blockages, and other issues that can impair the efficiency of the HVAC system. They place great emphasis on using top-notch materials and construction techniques to produce robust ducts.

This translates to a smoother operation of the HVAC system, resulting in reduced maintenance expenses and an extended lifespan of the system, ultimately benefiting both the building and its occupants in the long run.

Complies with Building Codes and Standards

Proper ductwork fabrication guarantees compliance with building codes and standards, which are designed to ensure the safety and comfort of building occupants.

By adhering to these requirements, ductwork manufacturers in the Philippines guarantee that the ducts are built to function effectively, ensuring optimal energy efficiency and indoor comfort for the building's occupants.